Created at the end of the 19th century, Minirectif, formerly “Manufacture de Pivotage Rubin”, specializes in watchmaking in Geneva and Cluses region.

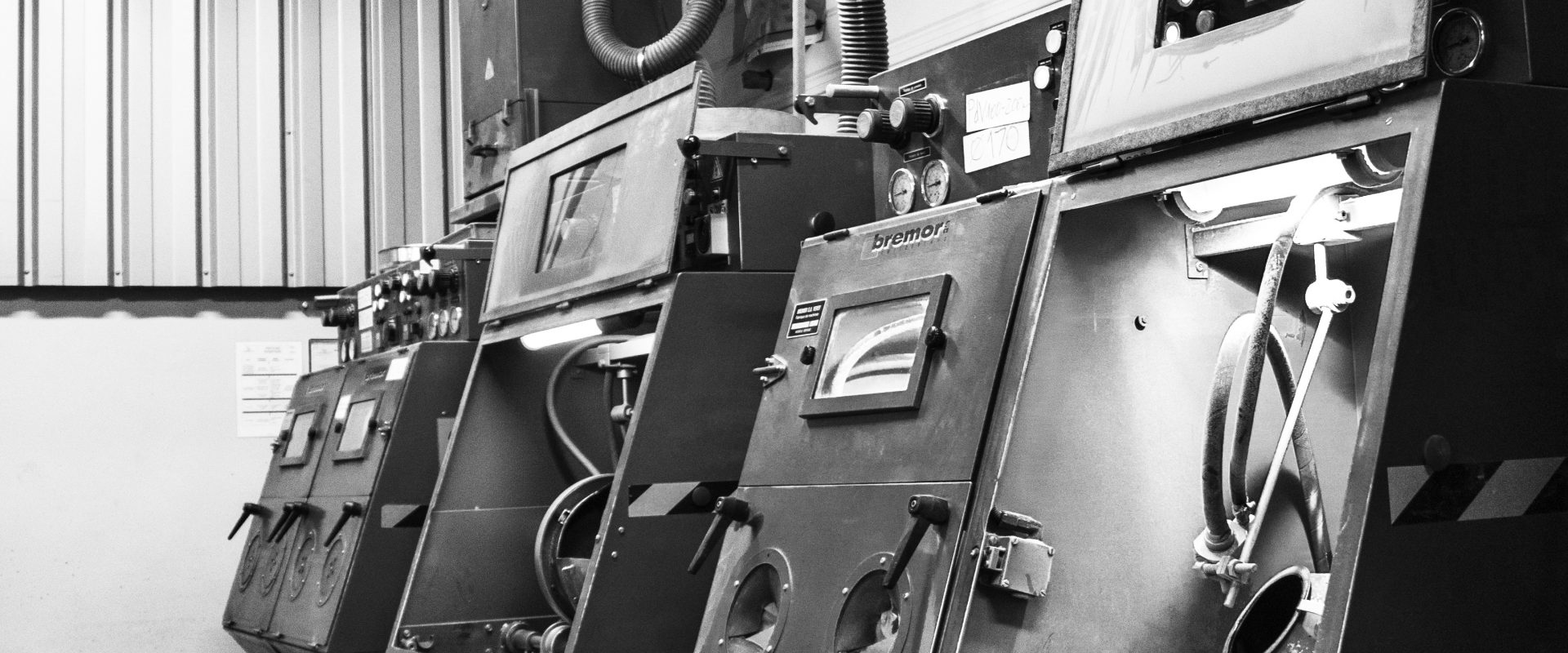

From 1978, our compagny specializes in centerless grinding, in addition to our historical activity. Since then, the company has continued to diversify in order to best meet the demands of its customers. This desire to remain at the cutting edge of technology is one of Minirectif’s cornerstones.

Mindful of its environmental impact, the company quickly invested in a wastewater treatment plant and a biomass boiler plant; thus, in 2005, Minirectif obtained dual ISO 9001 & ISO 14001 certification.

2 production sites

3500 m² of workshops

35 employees

Fields of activity

Aeronautics

Aerospace

Implantable Medical

Train

Automobile

Connectivity

Home automation

Luxury industry

G

rinding

Grinding is a finishing operation after machining parts of revolution in order to obtain dimensional and geometric tolerances of very high precision.

Grinding is the historical heart of our company. The skills acquired over the years allow us today to offer you grinding operations, threading, plunging, gap, pinching…

This technical mastery positions us as a leader in small dimensions (diameters less than 0.9 mm), while being able to offer you a treatment up to 200 mm in diameter.

«

Our CNC machine park allows us to propose to you the grinding between-points and in grippers, cylindrical and of forms.

»

V

ibratory finishing

Vibratory finishing, chemical-mechanical treatment, consists in finishing all types of parts in order to obtain the control of very fine surface states, as well as finishes such as :

- Polishing

- Micro-finishing

- Shelving

- Deburring

- Decalamination

- Deoxidation

These operations can be carried out after grinding, heat treatment or directly after machining, stamping, cutting, injection.

Our know-how, combined with our machinery, allows us to process your parts in bulk as in single pieces, with finesse and precision.

S

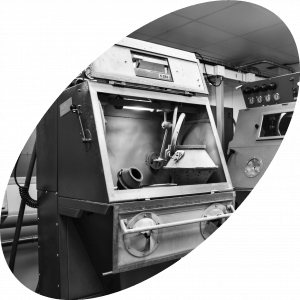

andblasting

Sandblasting, treatment by spraying abrasive media, ensures fine deburring or allows the achievement of specific aspects.

Specialist in this process, we offer a variety of operations, through the use of many media, such as :

- Glass or ceramic microbeads

- White corundum

- Glass powder

- Made from plants or plastics

- Metallic: stainless steel, brass, steel

«

Our production means guarantee rapid adaptation and execution to all your requirements.

»

H

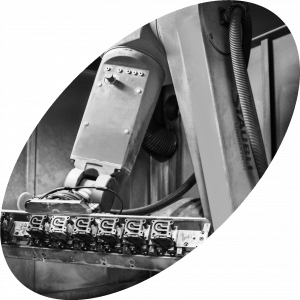

igh pressure deburring

High-pressure jet deburring is a process designed to remove detachable burrs by spraying a fluid (water or oil) onto robotic cells under high pressure (up to 1500 bar), while respecting geometries and surface conditions.

«

We are able to guarantee optimum deburring and an unequalled cleanliness rate.

»

L

aser engraving

Laser engraving is a process consisting in “eroding” the material thanks to the action of a large quantity of energy generated by a laser and concentrated on a very small surface.

Our 20 years of experience allow us to offer you marking on all types of materials, on flat or circumferential shapes, as well as markings such as DataMatrix, bar codes, drawings, texts…